beneficiation coal crushing

Beneficiation an overview ScienceDirect Topics

Beneficiation includes crushing, grinding, gravity concentration and flotation concentration. Beneficiation is followed by processing activities such as smelting and refining.

Selective Crushing of Run-of-Mine as an Important Part

Hard Coal Beneficiation Process Piotr Matusiak 1, Daniel Kowol 1,*, Tomasz Suponik 2, The results of laboratory tests for selective crushing susceptibility of steam coal and coke

Mineral Beneficiation and Processing of Coal Request

2021年5月11日 Beneficiation of coal of −4.76mm+3mm size fraction was investigated in a laboratory model Denver jig. Process variables were studied to analyze their effect on the

Coal Beneficiation Process Diagram Mineral Processing

The Problem with Coarse and Fine Coal BeneficiationThe Problem with Coal Recovery and Cleaning by FlotationCoal Flotation ProblemsCoal Beneficiation Process

Economic and operating conditions make it important to provide a simple, low cost, efficient method for recovering fine coal from washery waste. Not only is the water pollution problem a serious one, but refuse storage and disposal in many areas is becoming limited and more difficult. Many breakers and washeries efficiently han在911metallurgist上查看更多信息预计阅读时间:13 分钟

Coal beneficiation: Agreement benefits economy and

2021年8月2日 Acrux Sorting Coal (ASC) has signed a coal beneficiation agreement with two wholly owned subsidiaries of Wescoal, whereby ASC will deploy advanced sensor

Raw material preparation and coal refinement

Raw material preparation and coal refinement. Mineral beneficiation is a process that seeks to improve the quality and value of ore by cleaning and purifying it. Impurities and other contents are separated to achieve a

Beneficiation process and separation method,crushing

2020年9月17日 Beneficiation process and separation method . Crushing: The process of breaking the ore blocks with a particle size of 500-1500mm from the mine to a particle

Coal Beneficiation Technology Mineral

2016年12月14日 The purpose or beneficiation of coal is to reduce the concentration of unwanted material or gangue which in the coal industry is referred to as mineral matter or ash. This is so as to reduce transport

en/coal hammer iron beneficiaiton crusher china.md at

Contribute to lbsid/en development by creating an account on GitHub.

Mineral Beneficiation and Processing of Coal SpringerLink

2021年5月11日 Coal beneficiation using spirals is an age-old technique and is still widely accepted, operated satisfactorily worldwide to reduce the ash content of the coal. W. S. (1980). Selection guidelines for size and type of vibrating screens in ore crushing plants, Chapter 15. In A. L. MularR. B. Bhappu (Eds.), Mineral processing plant design

Raw material preparation and coal refinement

Raw material preparation and coal refinement. Mineral beneficiation is a process that seeks to improve the quality and value of ore by cleaning and purifying it. Impurities and other contents are separated to achieve a

COAL BENIFICIATION Energy.gov

2013年2月21日 History of Coal Beneficiation in Tata Steel 1952 : • First Coal Washery in Asia put up by Tata Steel West BokaroJharia : Chance Cone Process • Introduction of rotary breaker for deshaling and crushing simultaneously for Jharia coal. 7 Beneficiation : Seam processing strategy CUM WTS IN THREE DIFF SEAMS 0.00 20.00 40.00 60.00

Beneficiation process and separation method,crushing

2020年9月17日 Beneficiation process and separation method . Crushing: The process of breaking the ore blocks with a particle size of 500-1500mm from the mine to a particle size of 5-25mm. The methods include crushing, crushing, chopping, etc., generally in three stages: coarse crushing, medium crushing, and fine crushing. Grinding: Mainly on

Coal Beneficiation Technology Mineral

2016年12月14日 The purpose or beneficiation of coal is to reduce the concentration of unwanted material or gangue which in the coal industry is referred to as mineral matter or ash. This is so as to reduce transport

en/the definition of clean coal crusher capacity.md at main

Contribute to lbsid/en development by creating an account on GitHub.

General layout plan of beneficiation crushing and

2022年6月25日 There are many general layout schemes of the crushing and screening plant, which can be divided into two sections of open circuit, two sections of closed-circuit, three sections of open circuit, three sections of closed-circuit, and four sections of a closed circuit according to different production processes. And each process can be configured

silica sand beneficiation process equipment LinkedIn

2023年4月7日 The beneficiation process typically involves crushing and grinding the raw material to the desired size, followed by gravity separation, magnetic separation, or froth flotation.

COKING COAL BENEFICIATION Part 2 SciTech Connect

2018年7月30日 The coking coal resources can be augmented by recovering extra low ash coking coal from washery middlings by suitable beneficiation processes (Jha, 2012).This possibility has been established from tests. The middlings were crushed to 13 mm and 3 mm and thereafter subjected to float and sink tests.

Biden boosts clean energy in coal country despite facing

2023年4月4日 April 4, 2023, 6:01 AM 2 min read. WASHINGTON Communities formerly dependent on coal and other fossil fuels could get an entrée into the clean-energy economy through new federal funding the Biden administration is announcing Tuesday. Through tax credits and competitive grants, the administration hopes wind farms, solar fields and

Mineral Beneficiation and Processing of Coal SpringerLink

2021年5月11日 Coal beneficiation using spirals is an age-old technique and is still widely accepted, operated satisfactorily worldwide to reduce the ash content of the coal. W. S. (1980). Selection guidelines for size and type of vibrating screens in ore crushing plants, Chapter 15. In A. L. MularR. B. Bhappu (Eds.), Mineral processing plant design

Coal Mining and Production International Finance

Coal beneficiation is based on wet physical processes such as gravity separa-tion and flotation. Beneficiation produces two waste streams: fine materials that are discharged Release of dust from crushing and other coal processing and beneficiation operations should be controlled. • Control of the release of chemicals (includ-

Enhanced Coal Comminution And Beneficiation using

1991年6月16日 One of many ways of using coal as a fuel is to pulverize it into ultrafine size (200 mesh; < 75 microns); preparing dense slurries containing coal, water and small amounts of additives. This work describes an electrohydraulic (EH) approach to coal comminution where we use high energy electric sparks in water to generate shock waves

TECHNOLOGIES F0R FINE COAL BENEFICIATION IN

2013年2月21日 PROBLEMS IN EXISTING COAL BENEFICIATION PLANTS • Increased production from Lower Seams. • Enhanced supplies from mechanical opencast mine consisting considerable proportions of free dirt, boulders and other lumpy extraneous materials. • Increased proportions of fines below 0.5 mm in the feed • Change in the

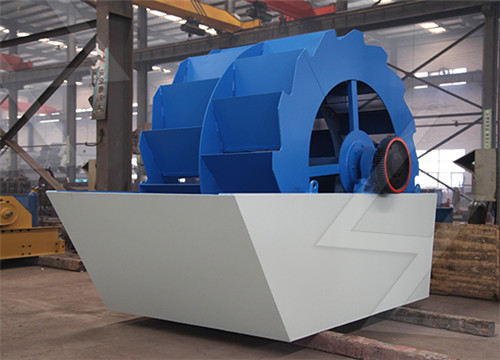

Coal Beneficiation Multotec

We supply coal beneficiation equipment for the entire process, from R.O.M stockpile to dewatering. As experts in the field with over 40 years’ experience, our team of metallurgists will assist you in optimising your coal benficiation plant. Remove contaminants and lower-grade coal from the coal stream. Achieve the sharpest particle

Coal Beneficiation Technology Mineral

2016年12月14日 The purpose or beneficiation of coal is to reduce the concentration of unwanted material or gangue which in the coal industry is referred to as mineral matter or ash. This is so as to reduce transport

en/the definition of clean coal crusher capacity.md at main

Contribute to lbsid/en development by creating an account on GitHub.

General layout plan of beneficiation crushing and

2022年6月25日 There are many general layout schemes of the crushing and screening plant, which can be divided into two sections of open circuit, two sections of closed-circuit, three sections of open circuit, three sections of closed-circuit, and four sections of a closed circuit according to different production processes. And each process can be configured

11.11-2 EMISSION FACTORS 2/80 US EPA

2015年9月10日 gasification, raw gas cleaning, and gas beneficiation. Each of these operations consists of several steps. Figure 11.11-1 is a flow diagram for an example coal gasification facility. Emissions from coal storage, handling, and crushing/sizing mainly consist of coal dust. These emissions vary from site to site depending on wind velocities